Tools for every kind of Hydraulic Hammerare for every brands in the market, such as INDECO, ATLAS COPCO, KRUPP, MONTABERT, RAMMER, FURUKAWA, ITALDEM, SOCOMEC, PROMOVE, NPK, CASE, CP, CATERPILLAR, VOLVO, ROTAIR, etc.. Our choice of steel and heat treatments aim for the best combination of wear resistance and tenacity, in order to guarantee a longer lifetime of our hammer tools, even in the hardest conditions. We manufacture tools of different types and shapes, suitable for every application.

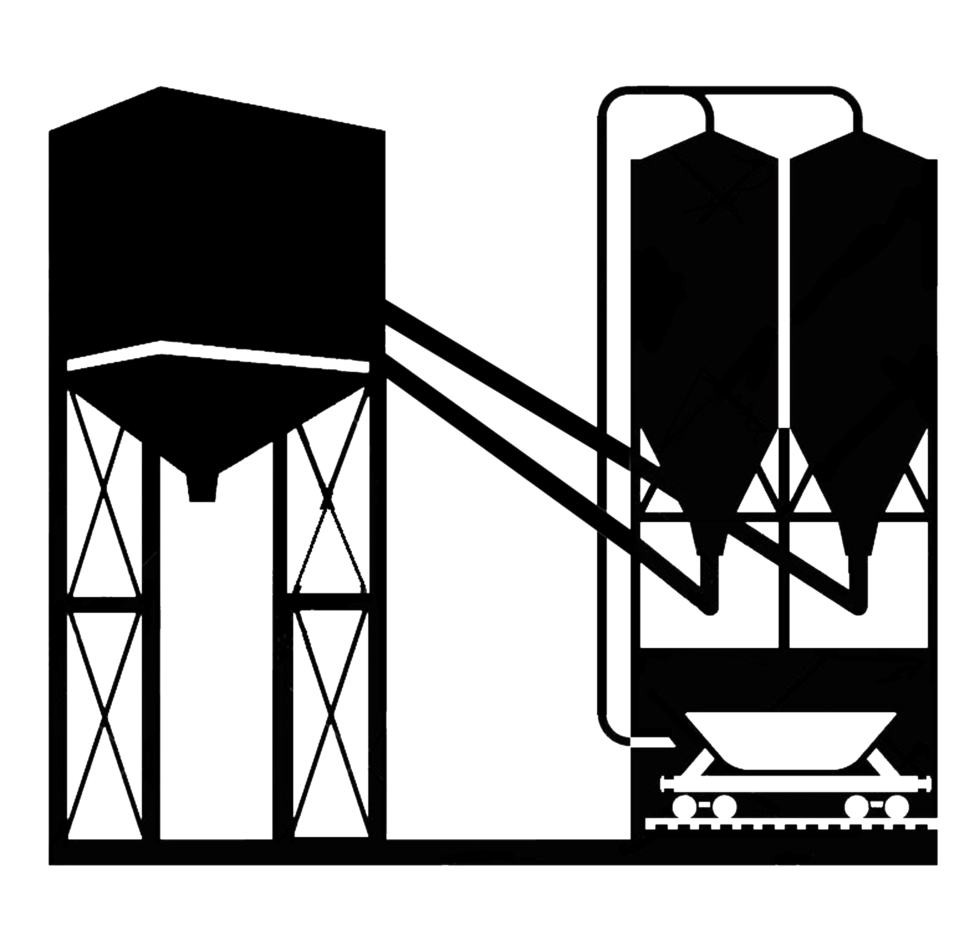

PRODUCTION CYCLE

STEEL USED

Our tools use a hardening steel with a nickel component that increases the thermal conductivity during the treatment, allowing to have a homogeneous hardness between the external surface and the heart of the tool.

ULTRASONIC CHECK

At the time of purchase, the steel undergoes an initial ultrasonic check to look for any internal anomalies. Surface imperfections are eliminated during the processing phase. In this stage, 6 mm up to 10 mm of material are removed depending on the diameters.

DIMENSIONAL CHECK

After processing, a dimensional check is carried out before heat treatment.

HARDNESS CHECK

The production cycle ends with the hardness check, which must remain in a range between 48 RHC and 50 RHC (higher values increase the fragility of the tool and the chance of break and failure). The hardness check is carried out on each tool produced, with a single impression for lengths up to 800mm; and with two or three impressions for longer lengths.

[PDF]